Quick Navigation

If your car engine is revving when you brake, you should immediately find out what the problem is.

In this post, we’ve highlighted several causes of this issue and how to fix them. These are as follows:

A Leakage In The Brake Booster

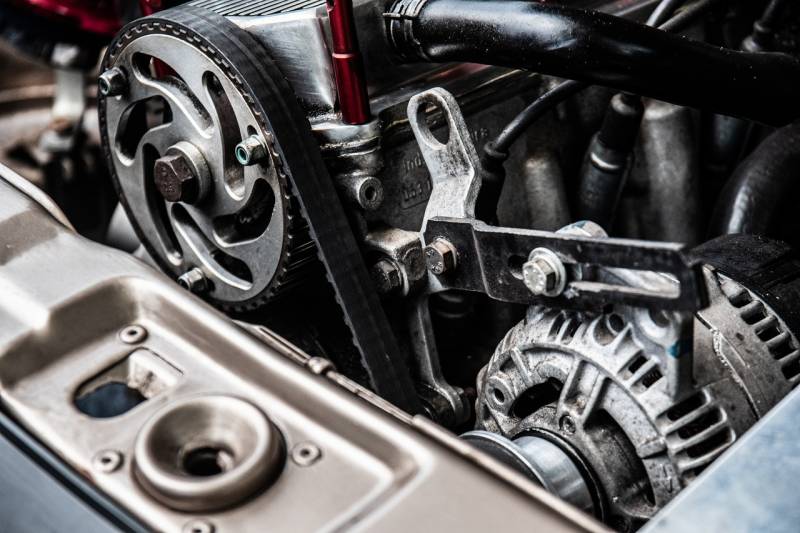

If your car engine revs when braking, the first thing to look at is the brake booster. This is a vital part of the braking system. The brake booster improves the master cylinder setup utilized to lower the pedal pressure required for braking.

It applies a booster set up to work with the master cylinder to provide higher hydraulic pressure to the brakes and lower force used on the brake pedal via a brake booster push-rod.

If the brake booster has a leakage, it allows additional air into the intake manifold. As a result, the air enters the engine and causes the revving. Other signs of a leakage in the brake booster include leaking brake fluid, sinking brake pedal, insufficient braking pressure, and engine misfire.

How To Fix It

Repairing a brake booster is not an easy thing and should be left for professional mechanics. However, if you want to replace the brake booster on your own, you can still go ahead and do it.

The first thing is to get the right tools such as screwdrivers, wrenches of different sizes, and a new check valve.

Step 1: Turn off your car’s engine and pump the brake pad until you have bled out all of the fluid in the brake fluid system. Make sure the brake pedal is depressed as you start the engine at the same time. If the vacuum system is intact, then your brake booster is worn out.

Step 2: Before concluding that the brake booster is bad, you should inspect the check valve first. The check valve is typically located where the vacuum line connects to the brake booster. After identifying the valve, remove the clamps and take out the valve line using a screwdriver or wrench.

Step 3: If you suspect that the check valve is faulty, remove it and replace it with a new check valve. Next, reconnect the vacuum hose and check if the problem is restored. If the pressure is okay, you’re good to go, but if not, replace the brake booster.

Step 4: Identify the location of the brake booster. It is usually located behind the firewall of the brake master cylinder. Next is to disconnect the clamps and vacuum line. Then, separate the brake booster from the master cylinder.

Step 5: Remove the worn-out brake booster and replace it with the new one. Fasten the new brake booster in position. Slide the rubber hose over the fittings and reconnect the clamps and vacuum line to the booster.

Replacing a brake booster is a very delicate thing as you can end up damaging the brake lines. That’s why it is recommended that professional mechanics remove a worn-out or leaking brake booster.

A Bad Brake Master Cylinder

The brake booster and master cylinder work hand in hand. They both multiply the pressure applied on the brake pedal. As a result, it allows the driver to modulate the brakes smoothly as you slow down. Therefore, if the brake booster or master cylinder is damaged or worn out, the braking system will fail to function.

This leads to the car engine revving when braking. Other signs of a bad master cylinder are worn out master cylinder seals, abnormal clutch pedal behavior, spongy brake pedal, brake fluid leak, sinking brake pedal, and check engine light comes on.

How To Fix It

Replacing a master cylinder is easy if you have the right tools with you. Here is a step-by-step guide on how to change a worn-out master cylinder with a new one.

Step 1: The first step to replace a damaged brake master cylinder is by locating it. The master cylinder is usually located under the brake fluid reservoir. The brake master cylinder should have brake fluid lines connected to it.

Step 2: Unfasten the master cylinder using a wrench. Remove the nuts that connect the master cylinder to the brake booster and firewall. Additionally, you should use a line wrench to loosen the brake lines from the master cylinder ports.

Step 3: Next step is to disconnect the electrical connections and other fittings on the fluid lines. Connect the fittings to the new brake master cylinder. Depending on the type of vehicle you’ve, you may be required to transfer the fluid reservoir to the new cylinder.

Step 4: Bleed the new brake master cylinder. Bleeding the master cylinder helps to remove the air out of the system, which may prevent the transfer of force. Bleed the new master cylinder until all the air has disappeared. You may need a helping hand when bleeding your master cylinder.

Step 5: After bleeding the brake master cylinder, fasten it in place. Set up all the brake lines and tighten the nuts. Additionally, you should tighten the lines using a line wrench. Finish the installation by topping off the reservoir.

If you install the brake master cylinder correctly, you will no longer have to worry about your car engine revving when you brake.

Bad Throttle

If the throttle is damaged or not working correctly, it may cause the car engine to rev when braking. The throttle may hang up and not close totally.

As a result, the car engine may maintain or even increase its RPM when parking. But if the throttle is working correctly, the engine should return to idle when you park your vehicle.

The throttle is a vital part of the air intake system as it controls the flow of air into the engine, which is utilized to combust fuel in the pistons. Therefore, having a good throttle is vital as it allows the right amount of air to enter the engine.

Apart from your engine revving up, other signs can indicate a bad throttle. These include poor fuel economy, airflow disruptions, electrical issues, slow or uneven acceleration, dirt buildup, high idle, and check engine light.

How To Fix It

Before replacing the old or worn-out throttle body, try cleaning it and see if it will function properly. If not, then you can replace it with a new throttle body.

Step 1: Start by locating the throttle body. If your vehicle features the traditional carbureted engine, it will be integrated into the carburetor. On the other hand, if your vehicle features a modern fuel-injected engine, the throttle body will be located between the air filter and the intake manifold.

Step 2: Switch off the engine and remove the air duct. Inspect the throttle body if it has any wearing and replaces parts that show signs of damage.

Step 3: Pull out the cables from the throttle and remove all the hoses. Also, you should remove the screws that hold the throttle body.

Step 4: Next step is to remove the throttle body after disconnecting everything. Clean all the parts and ports. Ensure there is no carbon buildup on the parts.

Step 5: Make sure the new throttle body is similar to the previous one. Install it in position and fasten the screws. Then, connect all the parts that you disconnected earlier. When you’re done with the connection, start the engine and test your new throttle body.

N/B: In some cases, you may not have to replace the entire throttle body. If the throttle body pressure has a problem, you can correct the engine revving problem easily. Adjust the throttle stop to have your engine functioning well.

Bad Oxygen Sensor

Another overlooked part of your car that can cause problems is the oxygen sensor. This component checks the ratio of air and gasoline in your car’s engine so that the ECU can adjust it if needed. If the oxygen sensor is bad, it may cause the engine to rev as you brake.

Besides, it can also cause poor gas mileage, emission test failure, rough engine idle, and check engine light come on.

The revving when stopping your vehicle occurs when the oxygen sensor wrongly detects that your air-fuel mixture is too much fuel. It ends up signal the computer to send in more air, which can cause the revving.

It is recommended that you change your oxygen sensor after every 60 000 to 90 000 miles. So, if you’ve exceeded this mileage, then you should replace your oxygen sensor as soon as possible.

How To Fix It

If the sensor is dirty, you can clean it and return it in its place. But if it is damaged, you will have to replace it. Here is the procedure that you should follow:

Step 1: Locate the bad sensor on your vehicle. Oxygen sensors are usually located near the exhaust pipe on each side of your vehicle’s catalytic converter. Test and identify which sensor is bad and remove it.

Step 2: Unbolt the retaining bolts using a socket set. Disconnect the sensor from the electric wiring harness.

Step 3: Scrub the metal tube-shaped end of the sensor with a wire brush to eliminate excess dirt and grime on the sensor. Utilize compressed air to spray and clean it. If possible, put some gasoline in a container and place half of the metal tube-shaped part of the senor in the container with gas. Leave it overnight.

Step 4: Remove the sensor from the gas the following day and dry it using a towel. You can now re-install the senor. Test the sensor and if it doesn’t work, replace it with a new one.

Summary

Most of the issues of a car engine revving when braking can be diagnosed at home. All you need is to have the right tools and follow the right steps.

If you cannot handle the repairs by yourself, take your car to a professional mechanic. All the best as you fix your car issues!

Kevin has been hanging around cars and automobile magazines since he knew what a car is. He grew up in his father’s 1995 Mercedes E320 Wagon and Volkwagon Phaeton W12 2004. He rides his first car, a manual 1979 Porche 911SC.

Currently, he owns an Acura Integra GS-R. During his childhood, he showed a keen interest in how things actually work and fix them. This passion transforms into his eternal love for cars and bestows him an ideal position in one of the leading automobile companies; whenever he finds time, he takes out his Acura and opts for the longest possible route to find hidden wholesome pleasure in a road trip.

Want to read some of the articles written by Kevin? Head to our blog section to find out all the articles written by Kevin.